Analysis of I-U characteristic curves

For the analysis of I-U characteristic curves in PV systems, use an I-U characteristic curve recorder to compare measured characteristic curves with standard or predicted characteristic curves, taking into account environmental influences such as shading or temperature.

The PV Array Troubleshooting Flowchart is a comprehensive guide developed based on real-world experience, literature sources on PV module reliability, and expert input from the National Renewable Energy Laboratory (NREL). I-U curve recorders such as Fluke Solmetric PVA-1500 provide detailed insights to identify PV hardware performance issues. Factors such as shading, contamination, irradiance, temperature, and measurement methods can make measuring the performance of PV systems complicated.

Download

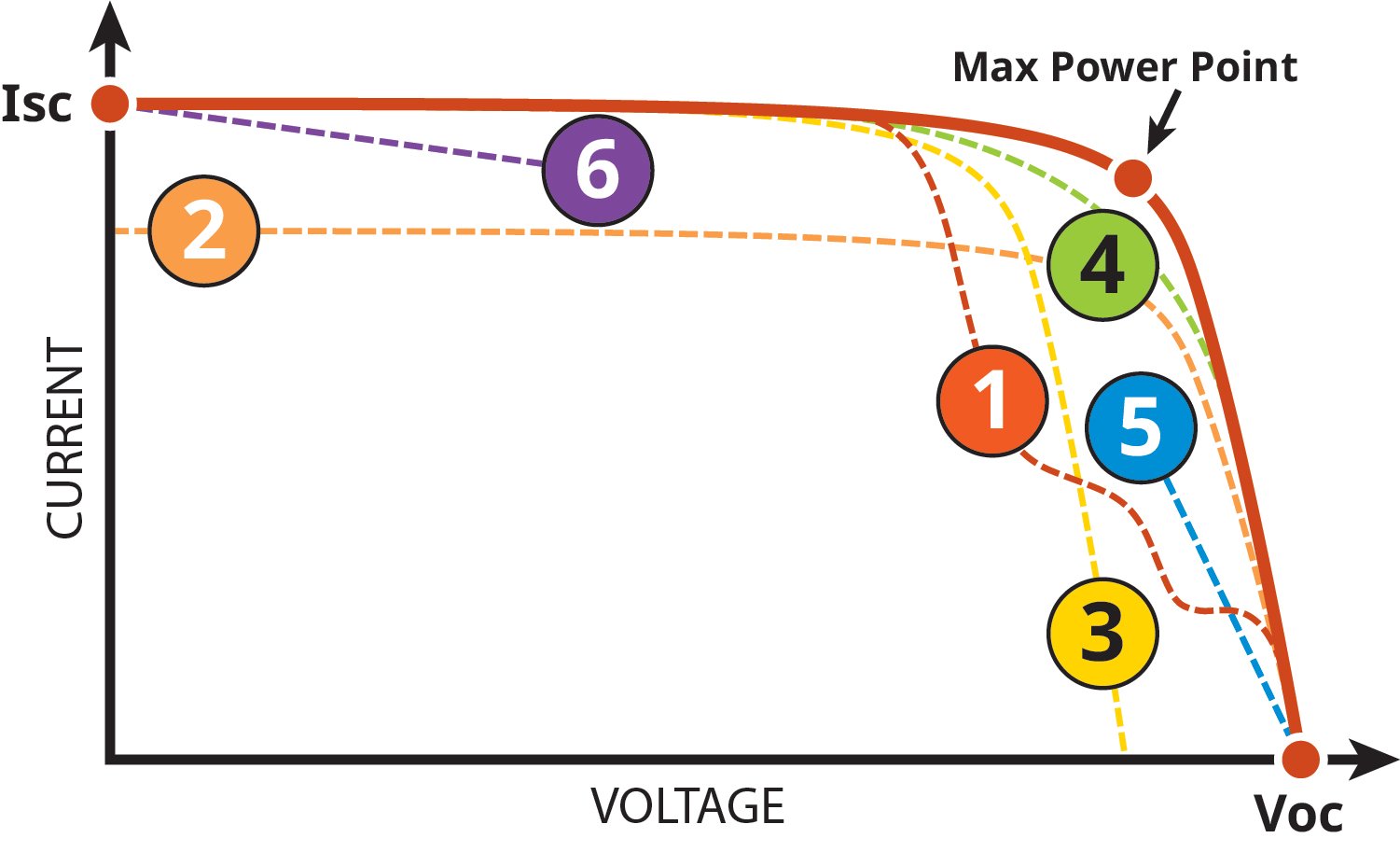

the free guide with flow chart This article discusses six types of deviation in I-U characteristics. The variances are numbered in the order in which they appear in the flow chart.

Acquisition of a usable I-U characteristic curve

First, check whether the test outputs a usable I-U characteristic curve. If this is not the case, check whether the test leads are connected properly. If so, the source circuit may not be closed. Check if a pre-fuse is installed; if so, check the fuse for continuity. If the pre-fuse passes the test, the problem may be with the wiring of the source circuit. Before checking for faulty modules, look for broken module connections and signs of damage such as burn marks.

In rare cases, tests output an I-U characteristic that has narrow vertical signal failures or downward peaks. The cause can be a loose contact, e.g. caused by a damaged test lead or an incorrectly crimped butt connection. If the loose contact is in the PV source circuit, isolate it and make the necessary repairs.

Normal Form & Performance

In the event of performance problems in the field, a comparative value is required, often based on the module's nameplate data or on measurements of adjacent circuits. I-U curve recorders such as the Fluke Solmetric PVA-1500 use software that predicts performance characteristics under standard test conditions, including on-site conditions. A normal form of the I-U characteristic curve and a power factor between 90% and 100% usually indicate the correct functioning of the PV source circuit or module.

Identification of I-U characteristic curve deviations

Different types of deviations can occur with I-U characteristic curves, each of which has several possible causes. These deviations can manifest themselves as steps or incisions in the characteristic curve and indicate a deviation in current due to problems such as shading or cell damage.

1. Stepped I-U characteristic curve

Steps or incisions in the I-U characteristic curve are the first type of deviation. They are due to a deviation in the current in the tested circuit. The stages in the characteristic curve occur when bypass diodes are activated and pass the current past cells that are weaker or receive less radiation. The number and width of the steps vary depending on the intensity and extent of shading. Many conditions result in deviation in current, such as uneven contamination, partial shading, damaged cells or cell strands, or short-circuited bypass diodes.

2. Low short-circuit current Isc

In an otherwise normal I-U characteristic curve, an Ipsc value below expectations can be caused by operating errors, low irradiance, shading, contamination or performance problems of the module. Because you may be able to resolve some of these issues, this second type of variance is addressed early in the troubleshooting flowchart.

3. Low open-circuit voltage Uoc

The third type of deviation in the troubleshooting flow chart is a low Uoc value. An incorrect measurement of cell temperature is most likely to cause a low open-circuit voltage. In addition, shading can reduce the ROC value under certain test conditions. Hardware problems are also possible. However, since open-circuit voltage has a lower aging rate than many other PV module parameters, you should consider other causes before concluding that there is a causal relationship between cell degradation and low Uoc.

4. Rounder bend

A bend that is rounder than expected characterizes the fourth type of deviation in I-U characteristic curves. It is often difficult to tell whether an area with rounder bending represents a pronounced disturbance of the I-U characteristic curve, or whether it is a deception due to changes in the characteristic curve slope. The round shape of the bend alone is probably a manifestation of the aging process. You'll need to re-inspect the circuit and observe it over time to identify and track trends.

5. Low voltage ratio

The fifth type of deviation of the I-U curve is characterized by the fact that the slope of the vertical portion of the I-U curve is less than expected. You can detect this state by visually comparing the measured and predicted characteristic curves or by comparing the values of the stress ratio over the entirety of the strand measurements, whereby the characteristic curves must not have any steps due to mismatch effects. To calculate the stress ratio: Ump ÷ Uoc. The stress ratio is very suitable for identifying a strand with an atypical slope in the vertical I-U characteristic curve section.

6. Low amperage ratio

The sixth and last type of deviation in I-U characteristic curves is characterized by an above-expected slope in the horizontal section of the I-U characteristic curve. You can detect this state by visually comparing the measured and predicted characteristic curves or by comparing the values of the current ratio over the entirety of the string measurements, whereby the characteristic curves must not have any steps due to mismatch effects. To calculate the amperage ratio: Imp ÷ Isc The amperage ratio is very useful for identifying a string with an atypical slope in the horizontal I-U characteristic curve section. Before you look for hardware problems, you should rule out any measurement errors due to shading, contamination and irradiance.

Use of I-U characteristic curve recorders in troubleshooting

I-U curve recorders such as Fluke Solmetric PVA-1500 play a critical role in troubleshooting PV systems. Not only do they provide detailed data to identify problems, but they also support the documentation and monitoring of system performance over time.

Effective troubleshooting of PV systems requires extensive knowledge of the hardware and environmental factors. The use of modern tools such as Fluke Solmetric PVA-1500 and the structured practices described below can significantly improve accuracy and efficiency in diagnosing and resolving PV system performance issues.